Contractors in the field prefer masonry lintels, opposed to steel lintels. Sometimes estimators assume masons prefer steel lintels but this is a myth. Just ask the builders in the field. Masonry lintels aid speed of installation and reduces cost and lead times often associated with structural steel lintels. Also, and arguably most important, masonry lintels eliminates cracking potential at bearing points that is all too common with steel lintels. Visit FORSE for masonry lintel design support.

Masonry Lintels Basics

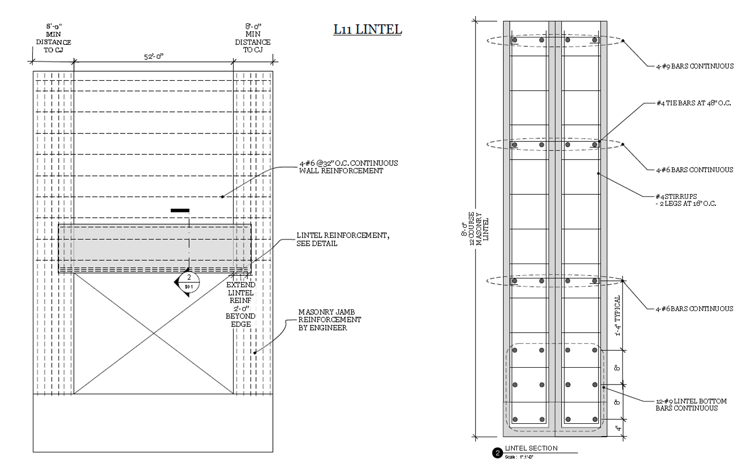

Design for masonry lintel spanning 52-feet to span performing arts stage opening

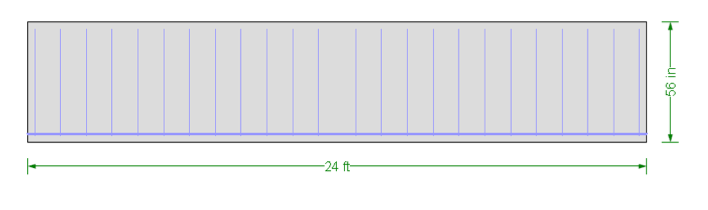

Length of Masonry Lintels

Temporary Support for Masonry Lintels

Supporting masonry lintels while they set up is much easier than some designers think. Short masonry lintels (generally under 12-feet) are commonly supported by wood or inverted steel angles. Longer masonry lintels are supported by wide flange steel or other solutions. Designers should not worry about means and methods.

Precast/Prestressed Concrete Lintels

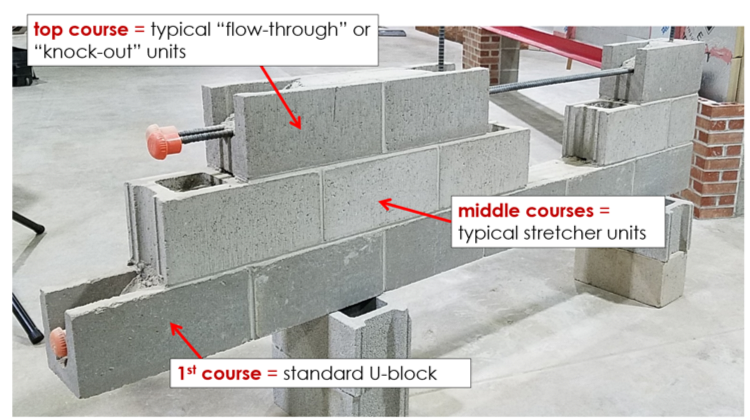

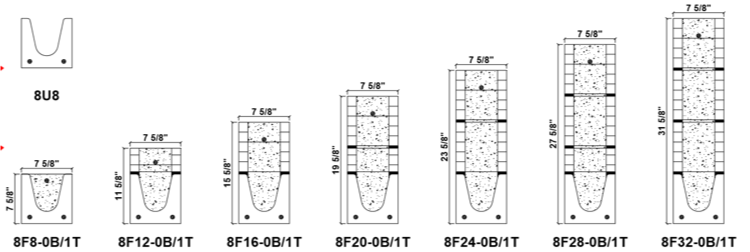

Some contractors prefer to use these lintels when it is approved by the architect and structural engineer. These units have cast steel tendons to provide temporary support. Once installed in the wall, rebar and grout is installed.

Prefabricated Masonry Lintels

Prefabricated masonry lintels aid speed of installation and reduces the cost and lead times often associated with structural steel elements. The use of masonry lintels also eliminates cracking potential at the interface of structural steel lintels and CMU. Structural steel expands and contracts at approximately 2.5 times the rate of masonry due to thermal impact. Prefab masonry elements are often build right on the site, or sometimes at an off-site location.